MIG / MAG welding is also known as ‘semi-automatic’ welding. The abbreviations stand for Metal Inert Gas and Metal Active Gas. They are actually two types. But because the only difference is the gas used, it is still considered the same kind. In these two welding processes, a wire is continuously supplied during welding.

Types of gases

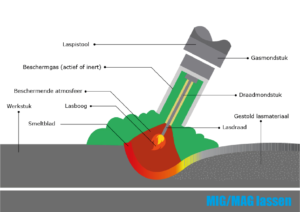

The arc is maintained between the wire and the workpiece. The weld pool is protected by a shielding gas. MIG welding is an inert gas (e.g. argon or mixtures of argon with Hydrogen gas and helium). MAG, on the other hand, is an active gas (e.g. carbon dioxide or argon mixed gases with Ar, CO2 and O2). An inert gas does not react with the weld pool and an active gas does. For example, an active gas influences the composition of the final weld.

Often mixed gases are also used between inert and active gases. MIG / MAG welding is the most widely used welding process today due to its versatility and speed. About 50% of all filler metal sold in the Netherlands is used for this process. It is so popular because of its mechanization and robotization capabilities, high flexibility and high deposition.

Welding methods

Welding can be done in three ways:

short arc (short arc), consisting of repeated short circuits;

spray arc (spray arc);

Pulse arc (pulsed arc).

A constant voltage is used with MIG / MAG. This is in contrast to TIG welding and welding with coated electrode. A constant current is used for this.