Bending pays off compared to straight pipe welded joints

The technological development of bending pipes and profiles has expanded enormously in recent years. Thanks to the technological improvement of bending machines, bending tools and materials, the bending process has become increasingly profitable.

In the past it has been very difficult to bend pipe with a radius of less than 2D (twice the diameter of the pipe). Because of this, many companies opted for a welding composition instead of bending pipes.

Today’s technology allows 1D (once the diameter of the tube) and even smaller than 1D. Of course under the condition that the right combination between material, machine and tools is chosen. CNC machining centers and the capabilities of CAD / CAM drawing programs make special tools for small radii easier to manufacture. Moreover, this benefits the cost price.

When a pipe is bent, two things can basically happen:

1. The outer wall of the pipe or bend becomes thinner and cracks open.

2. Wrinkles form on the inside of the pipe or bend.

Tools for bending

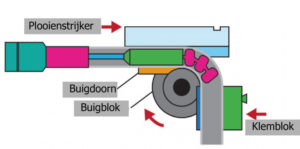

The minimum tools required for bending a bend are the bending block (around which the pipe is bent), the bending clamp block (which must hold the pipe in place when it is bent into the bending block), a ruler (which follows the pipe during the bending process) and a mandrel to stretch and keep the outside round. It is important to keep in mind that tools are just as important as the bending machine. Just like the properties of the available bending material.

Another important aspect for making good turns is the use of lubrication. The type of lubrication (grease, oil, special paste) depends on the material to be bent. The amount of lubrication to be used must be determined experimentally during the bending process.

The bending block is the main tool that determines the bending radius of the pipe. The shape of the bending block depends on the tube outer diameter (OD outside diameter) and the centerline radius (CLR central line radius).

The more accurate the radius must be, the more sophisticated and accurate the tool (the bending block) must be.

In addition to choosing the right bending block, it is also important to determine the correct grip length and grip surface by means of a clamping block. The clamping block often has a serration for more grip. The clamping block’s primary function is to firmly press the pipe against the bending block.

The length depends on the number of degrees of bend to bend (DOB degree or bend) and the CLR of the bending block.

The primary function of the bending ironer is to prevent wrinkles on the inside of the bend, especially with a small CLR. Correct adjustment of this tool is essential for a good bend and the life of the bending iron.

Thorns, if properly adjusted and the correct type selected, ensure that the outer diameter of the pipe does not fall. There are different types of thorns. The plug mandrel is mainly used for pipes with a thicker wall thickness and / or a large CLR. For so-called thin-walled pipes, special so-called ball thorns are used. These ball mandrels can be equipped with balls specially shaped for the bend to be bent.

In addition to all this, the bending machine must of course be suitable for the pipe to be bent or bend and it must be optimally programmed and adjusted in terms of pressure and the like.

DROSTE BEJAH bends its products with CNC-controlled bending machines of the brands BLM, Nissin, Pedrazolli and Veenstra, with or without a pick & place unit for full automation. She has many different bending tools standard in her program.

Contact DROSTE BEJAH for more information about the bending possibilities.